|

|

|

|

History Three different inventors aspires to be the inventor of the choke: William Rochester Pape (UK, Newcastle), William Wellington Greener(UK, Birmingham) and Fred Kimble (US). Pape was first with his patent 1866 that contains a constricted muzzle: patent 1866/1501. But the choke as just a minor part of that patent - mostly it’s a breech loaded gun. Kimble in US patented 1868 the same type of constriction, but that patent is just about the choke. In US that patent did have some practical use: to mechanically constrict the muzzle with a sliced muzzle and one form of the adjustable choke was invented. For obvious reasons that design can't be used on double barreled shotgun since the ribs keep the barrels together. These two first steps on the road was primitive and one could not say that the performance was neither predictable or gave a dense pattern. Greener that often refers to himself as the inventor of the choke developed 1874/1875 the Greener type of choke we know today: parallel section, cone, parallel section and muzzle. The question is: did he continue the work of Pape or the work of Kimble? Most experts today lean on Kimble as the inventor, but Pape was arguable first. And anyway the choke wouldn't have been the success it became if it hadn't been for Greener who developed the concept. And this little odd discussion about patents shows that neither Pape or Kimble was first with constrictions in the muzzle. The Manton brothers constricted the muzzles (free bored the barrel behind the muzzle more correct) on some of their guns - not for choke (adding density in the pattern) but to increase the pattern quality. And before that some Spanish gunmakers use both muzzles that was very opened funnel shaped as well as constricted. The latter was forgotten since they were a little bit complicated to load in the era of muzzle loading. The modern Greener choke

Greener choke This type of choke should prove to give a more even performance and predictable results and is more or less the one we use today in most cases. Greener experimented during 1874 a lot with the concept of choke, and 1875 he won the Fields Trials 1875. The technique was then soon adopted by all other makers and by 1880 most guns had choked muzzles. The Fields trials had an enormous impact as it was the most important publication of its time in this field. The result was not only that we could control the pattern density (pellet per area) but also pattern quality was enhanced from the true cylinder barrels. But should not take this fact to far - best pattern is normally achieved with 1/8 to 1/4. Greener is most likely also responsible for inventing the recess choke, a choke that in the beginning was developed to be able to give cylinder barrels some degree of choke - as long as there was enough barrel thickness to work with.

Recess choke that is sometimes used for making choke in a previous cylinder choke barrel. This type of choke has i modern time most been used by Russian gunsmith on the famous MC o/u guns. Interchangeable chokes The modern interchangeable choke was patented earlier than most people thinks; it was patented by Sylevester Rooper in US 1866. But it would take a while before this invention was adopted generally on the market. It was put on the market by Winchester 1959, and by 1970-ties it was regarded as a common thing to find on a shotgun. Since then it has been more or less impossible to sell a shotguns without interchangeable chokes unless we are talking about very expensive guns. When it was used by Winchester one can not by think of the reasons why they did so - but most likely it was a need for showing the market a new gizmo on the market, and it did give some manufacturing benefits: you don't need to bother about choke when making the barrel, whatever choke the buyer wants he or she can give the by changing chokes. The backside of this is that the barrel is not properly regulated and choked from how the barrel performs. The interchangeable chokes also gives the same length of the cone and parallel section - something that Greener knew was to be a dead end. The upside is that the gun owner can buy after market chokes which normally has way better performance than the original ones that normally performs rather badly. But as other things as ejectors and single trigger the interchangeable chokes can be a source of very complicated and strange problems. If the choke is not correctly aligned with the barrel the pattern can sometime jump around when the choke are replaced. Definition of choke Choke is the constriction in the last inches before the muzzle, and it is normally measured as the percentage of pellets that hits a 75cm circle at 35 meters.

But it is not only the constriction that gives the choke, the cone between the chamber and barrel, the cone before the constriction and the finish in the barrel also plays a large part. As the cartridge does, if the cartridge uses a plastic wad the difference in choke is normally somewhere around 1/2 to 1 step in choke (from say 1/2 to 3/4). How choke normally is stamped on barrels.

The table is valid for lead with plastic wad; normally there is a difference of approx. one degree of choke between plastic wads and fiber wads. Other things that has a impact on choke performance The amount of choke is not only a question about constriction between the barrels cylindrical part and the diameter of the muzzle. The most important things are: - the construction and material in the wad - the cone between chamber and barrel - the finish of the barrel - the angle of the choke cone - the length of the cylindrical part after the cone of the choke The last one first: the cylindrical part after the cone of the choke. The reason for this is to give the pellets some time to “calm down” before they leave the muzzle. If it’s to short the pellets distribution will be less even. If it's to long it will actually contradict the choke with a less dense pattern. The angle of cone (for the choke) normally has the following impact on choke performance: a short cone makes the choke more efficient (at the same constriction) in terms of how much choke it will perform. A longer choke has less choke efficiency (at the same constriction), but it normally gives a more even pattern. Barrel finish: the finish of the barrel has been and still is questioned, but normally a barrel with a very smooth surface works against the choke, that is less choke performance given the same choke (cone angle and length). But a barrel that has been lapped wrongly (a good smooth finish) but with variations in diameter can give very poor quality in pallet distribution since the pellet body is not given a stable state. And finally the cone between the barrel and chamber: one might wonder how this can affect the choke, and the reason is probably more indirect than directly. A sharp angle (short cone) increases the force needed to press the load and the wad over the cone, hence a higher pressure behind which in the next step gives a faster acceleration in the first inches of the barrel. And this effect in some way affects how the choke cone performs: the coke increases. The type of wad is rather easily understood: plastic wad (formed as a cup) normally gives one step more choke than if fiber wad is used. But how hard the wad material also have impact om choke performance. A very hard fiber wad has the same effect on the choke as poor barrel finish or very sharp angles in the cones. Choke performance The other side of pellet percentage is the area of the load, the higher the grade of choek the smaller the area the pellets are distributed over.

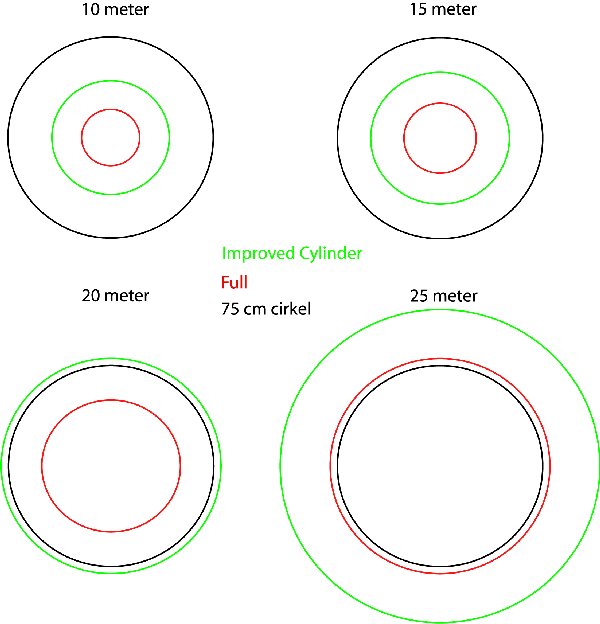

So the choke is defined as a percentage of pellets to hit a 75cm circle at 35 meters (often called pattern density), but it’s most important impact is that is adjusts the area we can hit the target with.

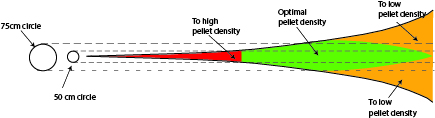

One should realize that the shot is not a cylinder - but a cone where the density of pellets are the variable.

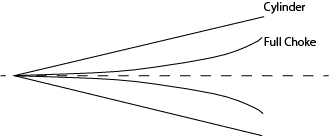

This can also be viewed from an other perspective as below, full choke VS cylinder.

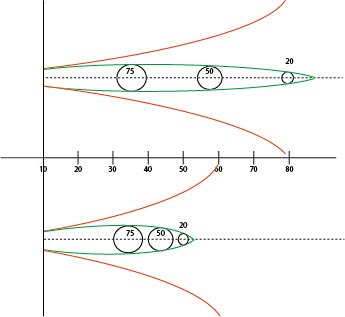

Can you choke to much? That the roundness of the pellets, the pellet size size and type/quality of the wad affects the pellet distribution I have mentioned earlier. But even choke has its limitations. According to new research done by BASC in Britain suggests that it has a max% pellets in a 75cm circle that hardly goes above 80%. To increased choke further is in the best case useless, in the worst case the % of pellets decreases, although it should actually rise.

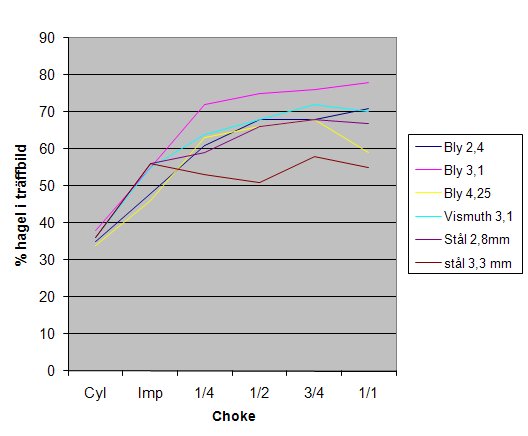

The chart above shows how some different cartridges loaded with different pellets behaves in a given barrel. Now, this chart does not mean that all cartridges behave like this in all weapons, but an example of how it actually can be. Source: BASC Ballistic Research Program. What might happen with increased choke however is that it compresses the distribution of the pellets, ie. you get the wrong distribution of pellets in the hit picture. And with the given definition of choke it does not matter if you have any pellets at one Euro coin or evenly over the 75 cm circle, the degree of choke will be the same. And the result is that far too many pellets fall into 50cm circle, which by definition reduces the hit rate of effective surface area by 50%, thereby reducing the probability to hit drastically. Or if you pass over the maximum restriction you can see that the spread is increasing and in some cases that may be even smaller number of pellets in the middle than around - sometimes called scratwheels.

Copyright 2016 © shotguns.se Last update: 2016-12-03 |